Graphene, new energy battery materials, polymer materials, precious metal purification, and high-performance synthetic resin materials.

In the early stages of R&D, double-layer glass reactors and multifunctional solid-phase reactors can meet the requirements.

Additionally, reactors can be customized according to customer needs.

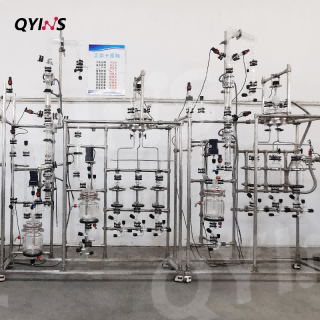

Multifunctional Solid-Phase Reactor System (with Collection Bottle)

Laboratory & Pilot Scale

Reactor Volume: 5L~100L

Equipped with distillation system, multifunctional reactor lid, and 6/7 lid openings

Jacketed glass, operating temperature -90℃~250℃

Handwheel lift and condenser optional

Fully sealed structure, no harmful substances released

Suitable for heating and drying/solid-liquid separation/crystallization/filtration/solid-phase peptide synthesis

Double-Layer Glass Reactor

Laboratory & Pilot Scale

Reactor Volume: 10L~200L

Equipped with condenser and reflux collection distillation system

Operating temperature -90℃~250℃

Dome-shaped lid with flange connections for excellent airtightness

304 stainless steel frame with optional Teflon coating for corrosion resistance; non-metallic materials in contact with the reaction substance

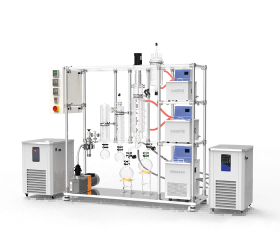

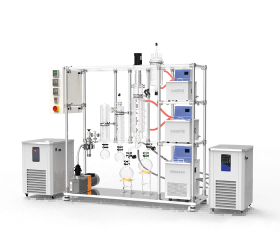

Glass Wiped Film Molecular Distillation System Type D

External dual-stage condenser and low-temperature reaction bath for better vacuum pump protection

High-temperature-resistant scraper, uniform film formation, short heating path, and high purification

High borosilicate glass, stainless steel, and PTFE gaskets for corrosion resistance

Transparent glass system for clear observation of the molecular distillation process

Magnetic seal drive ensures the vacuum system's integrity