Essential oils, also known as volatile oils, refer to oil-like liquids in plants that have an aromatic scent and are widely used in medicine, nursing, daily food products, and more. There are over 300 species of aromatic and medicinal plants in China that contain essential oils, but the content of essential oils in plants is usually less than 1%. The extraction and separation of essential oils have become research hotspots in this industry.

1. Extraction Techniques for Plant Essential Oils

1. Traditional Essential Oil Extraction

1.1 Extraction Method

Steam extraction involves crushing the plant material and placing it in a distillation apparatus, where steam is passed through, and the essential oil is distilled out with the steam. This method avoids overheating or charring that can occur with steam distillation. Steam extraction is currently the most widely used method and is suitable for the extraction of volatile components with low solubility in water.

1.2 Solvent Extraction Method

This method involves continuous reflux extraction or cold extraction using low-boiling organic solvents like petroleum ether or ether. The extracted solution is distilled or subjected to reduced pressure distillation to remove the solvent, yielding crude essential oil. This method has a higher yield, but it also extracts resins, oils, and waxes from the plant material, resulting in a higher level of impurities in the essential oil, so further refining is necessary.

Other traditional essential oil extraction methods include pressing and absorption, which are used for essential oils with higher content or those that need to maintain their original fresh fragrance. Traditional extraction methods generally have lower costs, longer extraction times, and more impurities.

2. New Methods of Essential Oil Extraction

2.1 Ultra-High Pressure Extraction Method

Ultra-high pressure extraction technology involves rapidly applying a fluid static pressure of over 100 MPa to the raw material at room temperature or a lower temperature and maintaining the pressure for a certain period to achieve rapid and efficient extraction.

2.2 Ultrasonic-Assisted Extraction

Ultrasonic-assisted extraction uses the intense cavitation effect and secondary effects generated by ultrasonic radiation pressure to increase the movement speed and frequency of extraction component molecules, enhance solvent penetration, and fully mix the extraction components with the solvent, improving extraction efficiency.

2.3 Microwave-Assisted Extraction

Microwave-assisted extraction mainly uses microwaves to penetrate the extraction medium, allowing the medium to absorb microwave energy, causing internal pressure to rise and cell rupture. The active components are released and dissolved into the extractant, which is then separated through subsequent filtration.

2.4 Supercritical CO₂ Extraction

Supercritical fluid extraction is a technique that uses a supercritical fluid as a solvent to extract specific components from solids or liquids and separate them. It features high extraction rates and purity.

Other common new methods of essential oil extraction include enzyme extraction, simultaneous distillation-headspace liquid-phase microextraction, subcritical extraction, and microcapsule-biphasic extraction. New extraction methods generally offer higher oil yields, shorter extraction times, and minimal damage to active components, but they require more complex processes and higher costs.

2. Separation Techniques for Plant Essential Oils

Essential oil obtained from plants is a mixture, and to obtain a single chemical component, further separation is required. Common separation methods include the following.

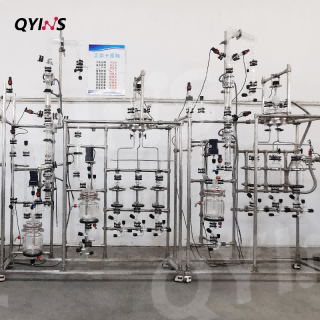

1. Molecular Distillation Method

This technique utilizes the difference in the free path of molecular motion between substances for separation. It can be operated in an environment far from the boiling point, featuring low distillation pressure, short heating time, and high separation degree. It significantly reduces the separation cost of high-boiling-point materials and effectively protects heat-sensitive substances. Therefore, molecular distillation is particularly suitable for high-boiling-point, heat-sensitive materials, especially essential oils and natural products whose active components are highly sensitive to temperature.

2. Crystallization Method

The cold crystallization method uses low temperatures to freeze and crystallize certain compounds in the essential oil, which are then separated from the liquid components to obtain a purer product. Crystallization has minimal pollution and typically requires multiple purifications to meet product requirements. In practical applications, glass crystallization reaction vessels are used for small-scale research, while stainless steel crystallization reaction vessels are used for pilot and production-scale operations.

3. Chemical Separation Method

The chemical separation method involves treating the essential oil components based on their structures or functional groups using chemical methods to separate them.

4. Chromatography

Silica gel and aluminum oxide column chromatography are common methods for separating essential oil components. Combining chromatography with distillation yields better results.

With the advancement of industrial development, essential oil extraction and separation techniques have gradually matured. The extraction and separation of essential oils from common plants such as mint, jasmine, rose, and lavender have reached a saturation point. The extraction and separation of small-molecule, pure natural plant essential oils have become a new market demand, placing higher requirements on laboratory separation equipment.