Extraction

To recover essential oils containing THC and CBD, ethanol solvent extraction is often the first step. The purpose of extraction is to produce oil free of particles and with a higher concentration of medically relevant compounds (cannabinoids) compared to raw hemp and cannabis. In the ethanol extraction process, process parameters vary depending on the raw material (quality and size), desired product, and other considerations. Ethanol extraction is frequently used due to its availability, efficiency, and relatively safe process.

Filtration

Single filter bags are suitable for certain coarse and pre-filtration processes. Lens filters are a new type of stacked filter that can replace diatomaceous earth filters for filtering, clarifying, and purifying tiny impurities in various liquids. These two filters can be used together to filter and remove impurities from the crude oil extracted from biomass. This critical step removes plant waxes and particles, which is key to producing a translucent final product and facilitates the next purification steps via evaporation and distillation.

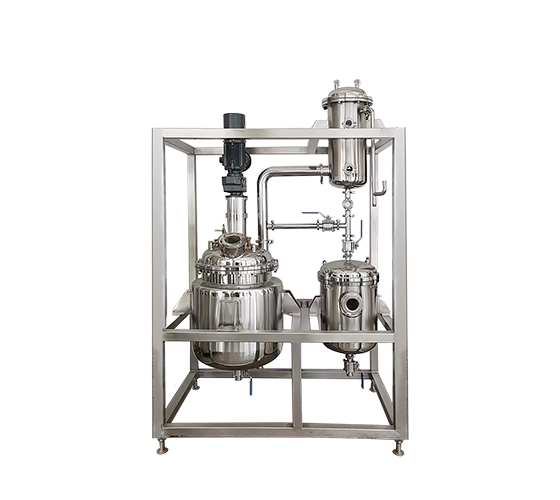

Evaporation

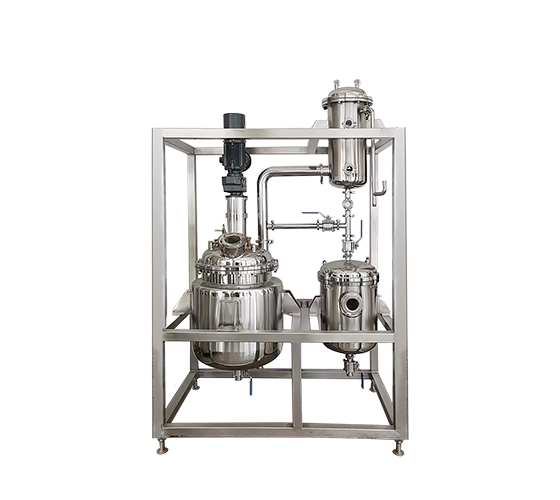

In a falling film evaporator, the feed liquid is added from the top of the heating tube. Under gravity, the solution flows down the inner wall of the pipe as a film, evaporating and concentrating. The vapor-liquid mixture enters the separator from the bottom of the heating tube. After separation, the liquid is discharged from the separator's bottom.

Solvent treatment is preferred over rotary evaporators. The crude oil mixed with solvent after extraction is dissolved in a falling film evaporator to obtain crude oil.

Decarboxylation

Decarboxylation is carried out in a double-layer reactor heated by thermal oil, allowing better separation of THC and CBD. The reactor body is available in two materials: borosilicate glass and stainless steel.

Distillation

Molecular distillation is a unique liquid-liquid separation technology. Unlike traditional distillation based on boiling point differences, it relies on the differences in the mean free path of molecules. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules escape from the liquid surface into the gas phase. Due to the differences in the free paths of light and heavy molecules, after escaping from the liquid surface, light molecules reach the condenser built into the main evaporator and are discharged, while heavy molecules cannot reach the condenser and are discharged with the mixed liquid. This achieves material separation.

Crystallization

If CBD separation is required, crystallization is appropriate. Pentane is used as the solvent. The crystallization process is achieved through temperature control, allowing solid-liquid separation to obtain isolated CBD. Our multifunctional filter reactor fills the jacket with heating and cooling media and stirs the precipitated crystals at a constant speed. Materials can be glass or stainless steel.

Drying

The vacuum drying oven is a box-type drying device that dries materials under negative pressure. Using a vacuum pump to draw out air and humidity creates a vacuum state in the working chamber, lowering the boiling point of water and speeding up drying. It is used for powder drying, defoaming, dehydration, curing, and drying in electronics production. It is widely applied in electronic chemistry, agricultural research, environmental protection, and other research fields.